High Speed Fully Automatic Bottom Sealing Machine

For bag on roll with or without core. Using a surface friction type unwinding system with a special rotating sealing unit. This machine utilizes a 4 piece servo motor drive which improves the production speed and stability. A lower temperature and longer time to seal means that the seal is of a higher quality than most machines of a similar class. Perforation lines are also kept at the same distance from the sealing line so that even when changing bag lengths, there will still be no defects. There is also a newly designed paper core feeding system that automatically changes new rolls to make sure that your processing is never at a standstill.

Add InquiryApplications

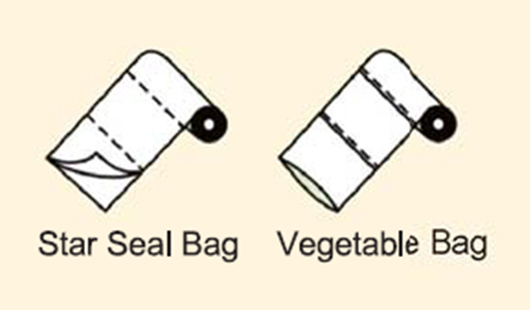

Star seal bags, vegetable bags and more

Raw Materials

HDPE, LDPE and more

Features

For bag on roll with or without core. Using a surface friction type unwinding system with a special rotating sealing unit. This machine utilizes a 4 piece servo motor drive which improves the production speed and stability. A lower temperature and longer time to seal means that the seal is of a higher quality than most machines of a similar class. Perforation lines are also kept at the same distance from the sealing line so that even when changing bag lengths, there will still be no defects. There is also a newly designed paper core feeding system that automatically changes new rolls to make sure that your processing is never at a standstill.

For bag on roll with or without core. Using a surface friction type unwinding system with a special rotating sealing unit.

| PRODUCTS | STANDARD SPECIFICATION |

|---|---|

| UNWIND BAG SEALING SIZE | 1.2m |

| FILM WIDTH |

100-850mm×1 Line 100-420mm×2 Lines |

| FILM LENGTH |

285-455mm(With 4 Sealing) 455-915mm(With 2 Sealing) 910-1820mm(With 1 Sealing) |

| SEALING THICKNESS | 0.02-0.06mm |

| FILM SPEED MAX |

120m/min(Without Core) 185m/min(Without Core) |

| BAGS SPEED MAX |

300pcs/min(With 4 Sealing) 150pcs/min(With 2 Sealing) 75pcs/min(With 1 Sealing) |

| SPEED FOR CHANGING THE ROLLS | MAX.6 ROLLS/PER MIN (WITHOUT CORE) |

| PRODUCTS | SIZE OF FINISHED ROLL(PRODUCT) |

|---|---|

| ROLL WIDTH |

150-680mm×1Line/Max(C Fold) 150-300mm×2Lines/Max |

| ROLL DIAMETER | 170mm/Max |

| PRODUCTS | SIZE OF FINISHED ROLL(PRODUCT) |

|---|---|

| ROLL WIDTH |

680mm×1 Line/Max 300mm×2 Lines/Max |

| ROLL DIAMETER | 170mm/Max |

| AIR PRESSURE SUPPLY | Dryer 6 Kg/5HP (EXCLUDED) |